Legacy waste management is one of the most pressing environmental challenges for Indian cities today. Decades of unscientific dumping have created massive dumpsites filled with mixed municipal solid waste. These sites release harmful gases, contaminate groundwater, and occupy valuable urban land. To address this, the biomining of legacy waste in India has emerged as a scientific and sustainable solution. Biomining involves the excavation, segregation, treatment, and reuse of old waste, turning what was once a problem into a resource.

While this approach has shown promising results in cities such as Delhi, Indore, and Nagpur, large-scale adoption still faces several challenges. This blog explains the major obstacles in legacy waste biomining and provides practical strategies to overcome them.

Why Biomining of Legacy Waste Matters

Before discussing the challenges, it is important to understand why biomining is critical for India’s urban future.

Scale of the problem: India has more than 3,000 dumpsites, holding over 235 million tonnes of legacy waste.

Environmental risk: Open dumps release methane, leachate, and toxic smoke, making them a health hazard.

Land scarcity: Municipalities lose thousands of acres of usable land to old landfills.

Resource recovery: Biomining recovers fractions such as Refuse Derived Fuel (RDF), compost-like material, recyclables, and inert waste.

In simple terms, biomining is not just about clearing garbage but about reclaiming land, reducing pollution, and promoting a circular economy.

Key Challenges in Legacy Waste Biomining

1. Heterogeneous Waste Composition

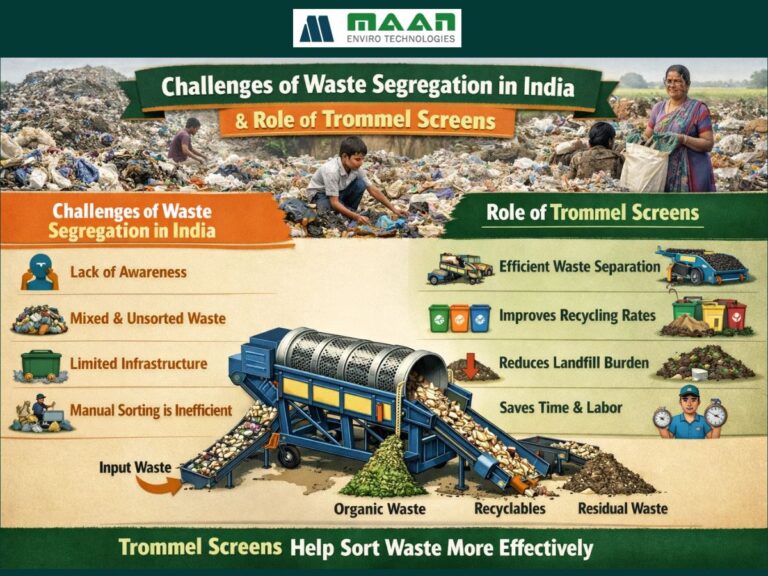

Legacy dumps contain decades-old waste mixed with plastics, metals, soil, and hazardous materials. This makes segregation difficult and slows down processing. Machines like trommel screens often face wear and tear when dealing with such mixed material.

Solution:

Use advanced screening technology with multiple size fractions.

Train workers to identify and separate hazardous waste during excavation.

Invest in durable equipment designed for mixed waste handling.

2. High Operational and Project Costs

Biomining projects cost between ₹800–1,600 per tonne. For large dumpsites running into millions of tonnes, this becomes a major financial burden for municipalities.

Solution:

Explore low-cost approaches to legacy waste management projects such as phased excavation, local resource recovery, and public–private partnerships.

Secure central and state government funding under schemes like Swachh Bharat Mission 2.0.

Encourage revenue generation from recovered RDF and recyclables.

(Read more about cost-effective methods in this article on low-cost approaches to legacy waste management projects).

3. Limited Land for Processing and Storage

During biomining, large volumes of waste need temporary storage and processing space. Many urban areas lack suitable land near dumpsites.

Solution:

Use modular machines that can be shifted and operated in smaller spaces.

Adopt on-site processing to minimise the need for secondary transport.

Plan for phased biomining so that cleared land can be reused for operations.

4. Leachate and Odour Control

Excavating old waste releases foul odours and contaminated leachate, which can spread into nearby areas. This leads to community resistance.

Solution:

Use leachate treatment systems such as bio-ponds and neutralisation tanks.

Apply odour control sprays and biological agents during excavation.

Engage with local communities to explain health and land recovery benefits.

5. Inadequate Technology and Skilled Workforce

Some projects fail because equipment is not suited for local waste conditions or because workers are not properly trained in handling legacy waste.

Solution:

Deploy customised machines such as trommel screens, air classifiers, and compost refiners.

Provide safety training, protective gear, and awareness sessions for workers.

Partner with technology providers to upgrade machinery as per site conditions.

6. Long Project Timelines and Delays

Large dumpsites can take years to remediate. Delays in approvals, funding, and technology procurement often slow down progress.

Solution:

Prepare a clear project roadmap with timelines and milestones.

Adopt biomining process automation where feasible to improve efficiency.

Regularly review progress with municipal authorities and contractors.

7. Post-Reclamation Land Use

Once a dumpsite is cleared, deciding how to use the reclaimed land is often a challenge. Without proper planning, the land may remain idle.

Solution:

Convert reclaimed land into public parks, green belts, or solar farms.

Use part of the space for decentralised waste management facilities.

Engage urban planners to ensure sustainable reuse of reclaimed land.

(Learn more in this detailed guide on how biomining transforms legacy waste into valuable resources).

Direct Answers to Common Questions

What is biomining of legacy waste?

Biomining of legacy waste is the scientific process of excavating old waste from dumpsites, segregating it, treating useful fractions, and reclaiming land for safe use.

How long does biomining take?

Depending on the size of the dumpsite and technology used, biomining projects may take from a few months to several years. Large city dumps can take 3–5 years.

What products come from legacy waste biomining?

Recovered materials include RDF for energy use, recyclables like plastics and metals, compost-like soil material, and inert fractions for construction.

FAQ Section

Q1: Why is legacy waste management important for Indian cities?

Legacy waste management is essential because dumpsites release toxic gases, leachate, and methane. Clearing them through biomining helps recover land, reduce pollution, and improve urban health conditions.

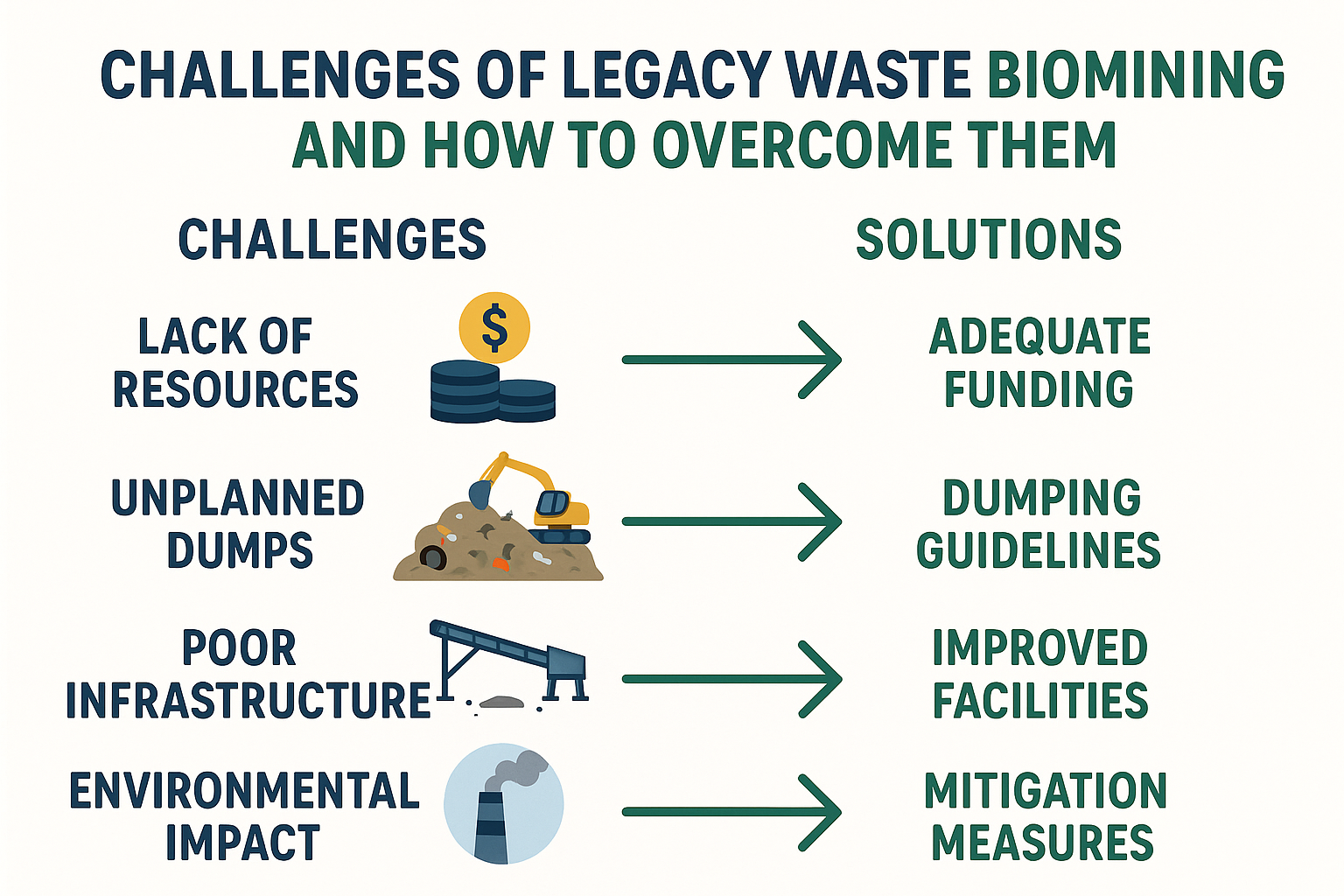

Q2: What are the main challenges in biomining of legacy waste in India?

Key challenges include mixed waste composition, high costs, leachate control, land availability, and project delays. Solutions involve advanced technology, phased excavation, and sustainable financing models.

Q3: How can municipalities reduce the cost of biomining projects?

Municipalities can reduce costs by adopting phased biomining, promoting resource recovery, and seeking central and state funding support. Partnerships with private firms can also help share investment and risk.

Q4: What role does Maan Enviro Technologies play in legacy waste projects?

Maan Enviro Technologies provides large-scale equipment and project solutions for solid waste management, including trommel screens, RDF plants, and composting units. The company supports municipalities and industries in executing sustainable legacy waste remediation projects.

Conclusion

Biomining of legacy waste is essential for India’s growing cities. Although there are challenges such as mixed waste composition, high costs, and limited land, practical solutions exist. With proper planning, modern equipment, and sustainable funding, legacy waste sites can be converted into productive land and valuable resources.

Moving forward, collaboration between municipalities, industries, and technology providers is key. Addressing these challenges effectively will help India achieve cleaner cities, safer environments, and a more sustainable urban future.