India’s cities are expanding rapidly, and so is the challenge of managing municipal solid waste. The country produces over 160,000 tonnes of waste every day, and the figure continues to rise with urbanisation and population growth.

Managing this waste efficiently has become a national priority. Traditional collection and disposal methods are no longer enough. To handle this growing problem, India is turning to advanced municipal solid waste equipment and modern waste management technologies that make the process cleaner, faster, and more sustainable.

This blog explores how smart machines such as Trommel Screens, Conveyors, Air Density Separators, Shredders and MSW Dryers are transforming modern waste management in India.

Understanding Modern Waste Management in India

Modern waste management focuses on more than just collection and dumping. It involves scientific processing, resource recovery and energy generation.

Main Objectives

Reduce the waste sent to landfills

Recover reusable materials and resources

Generate renewable energy from waste

Promote circular economy practices

By adopting advanced machinery and automation, cities and industries are improving waste handling and reducing environmental pollution.

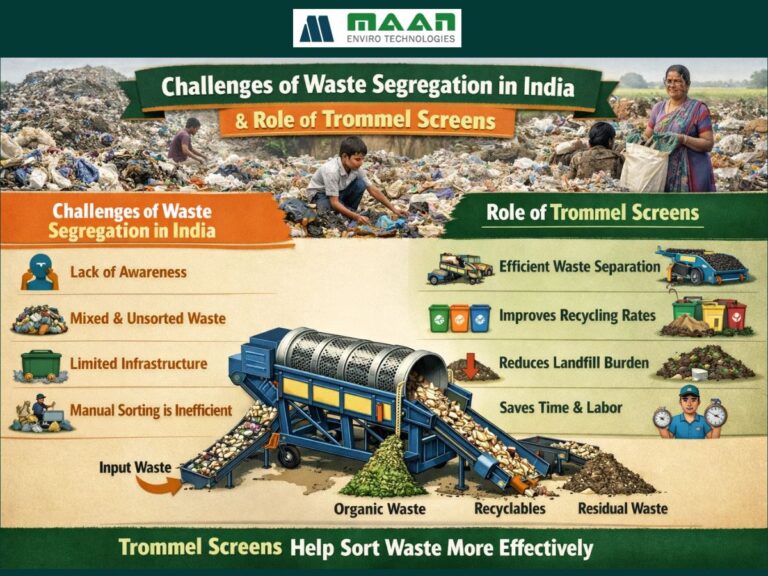

Trommel Screens: Accurate Waste Segregation

A trommel screen is a rotating cylindrical separator that classifies waste by size. It is widely used in municipal solid waste plants, composting facilities and biomining projects.

How It Works

As the drum rotates, smaller materials such as soil and compost fall through perforations, while larger items like plastics or stones move forward for further processing.

Benefits

Processes up to 100 cubic metres of waste per hour

Quiet operation with low power consumption

Minimal maintenance requirements

High screening accuracy

Trommel screens help city authorities recover recyclables and compost faster, improving plant efficiency and output quality.

Conveyors: The Core of Efficient Waste Facilities

Efficient material movement is essential for smooth operations in any waste processing plant. Conveyors enable the transfer of waste between machines safely and quickly.

Common Conveyor Types

Chain Belt Conveyors – Handle heavy or bulky municipal waste

Z-Type Conveyors – Lift materials to higher levels within the plant

Apron Conveyors – Suitable for wet or sticky waste streams

Why They Matter

Automated conveyors reduce manual handling, lower labour costs and improve workplace safety. They also ensure a continuous and steady flow of materials across multiple processing stages.

Air Density Separators: Advanced Material Recovery

Air Density Separators (ADS) are designed to separate light materials such as plastics and paper from heavier items like stones or metals using a controlled air stream.

Applications

RDF processing plants

Biomining and composting units

Resource recovery centres

Key Advantages

Produces clean and high-quality RDF

Minimises contamination

Maximises recovery of valuable materials

ADS units play an important role in turning waste into usable energy, helping India move towards a low-carbon future.

Waste Shredders: Reducing Waste Volume

Waste Shredders are heavy-duty machines that reduce the size of solid waste, making it easier to handle and process.

How They Help

By cutting large waste into smaller pieces, shredders make drying, composting and RDF production more effective. They also make transportation easier and more cost-efficient.

Features

High torque and durability

Capable of handling mixed waste

Automated feed systems for safe operation

Modern shredders help prepare waste for recycling or energy recovery while keeping operating costs low.

MSW Dryers: Preparing Waste for Energy Generation

MSW Dryers are used to reduce moisture in waste, which improves its calorific value and makes it suitable for energy production.

Advantages

Energy-efficient drying systems

Compact setup with minimal infrastructure needs

Operates at low temperature for fuel savings

Suitable for RDF and composting lines

These dryers play a vital role in producing Refuse-Derived Fuel (RDF) used in cement kilns and waste-to-energy plants across India.

Smart Integration for Maximum Efficiency

The true power of modern waste management lies in system integration. When all equipment is connected through PLC-based controls, plant performance becomes more efficient and predictable.

Through automation and digital monitoring, operators can track energy consumption, equipment health and output in real time. This results in higher productivity, reduced downtime and better resource recovery.

How Smart Machines Improve Waste Management

1. Saves Time and Labour

Automation replaces repetitive manual work, improving speed and reducing dependence on labour.

2. Increases Material Recovery

Accurate segregation means more recyclable materials can be recovered and reused.

3. Lowers Costs

Smart equipment requires less maintenance and consumes less power.

4. Protects the Environment

Reduced emissions, less landfill use and better recycling contribute to cleaner surroundings.

Direct Answer: What Drives Modern Waste Management in India

India’s progress in waste management is driven by the Swachh Bharat Mission, strict environmental regulations and the rise of automated waste processing systems.

Companies such as Maan Enviro Technologies are supporting this change with custom-built MSW equipment that ensures cleaner and smarter waste handling.

Challenges and Smart Solutions

| Challenge | Technology Solution |

|---|---|

| Inefficient segregation | Trommel Screens and Air Density Separators |

| High labour costs | Automated conveyors and shredders |

| Low material recovery | PLC-based sorting and monitoring systems |

| Landfill overflow | RDF production and composting plants |

Modern machinery is solving long-standing issues that manual systems struggled to address effectively.

Example of Urban Waste Transformation

In a recent municipal project, combining a Rotary Trommel Screen, Conveyor System and RDF Processing Line improved waste segregation accuracy by over 60 percent.

The initiative reduced landfill waste significantly and produced RDF with a calorific value above 3,000 kcal per kilogram, supplying clean fuel to local industries.

FAQs About Modern Waste Management in India

1. What is modern waste management?

Modern waste management uses advanced technology to collect, segregate, recycle and convert waste into resources or energy. It focuses on sustainability and environmental protection.

2. What machines are used in solid waste processing?

Common equipment includes trommel screens, conveyors, air density separators, shredders, and MSW dryers that work together to improve efficiency.

3. How does a trommel screen help?

A trommel screen separates waste based on size using a rotating drum. Smaller particles pass through perforations, while larger items move forward for further sorting.

4. What is RDF in waste management?

Refuse-Derived Fuel (RDF) is made from processed combustible waste. It is used as an alternative energy source in cement and power industries.

5. Why is automation important?

Automation improves speed, accuracy, and safety while reducing costs and environmental impact, making waste management systems more reliable.

Conclusion

Smart machines are reshaping modern waste management in India. By integrating automation, data monitoring and energy-efficient systems, cities and industries are achieving cleaner, faster and more sustainable waste solutions.

From trommel screens and conveyors to dryers and shredders, every machine contributes to a cleaner future. The focus is shifting from waste disposal to resource recovery and environmental preservation, creating a sustainable foundation for the next generation.