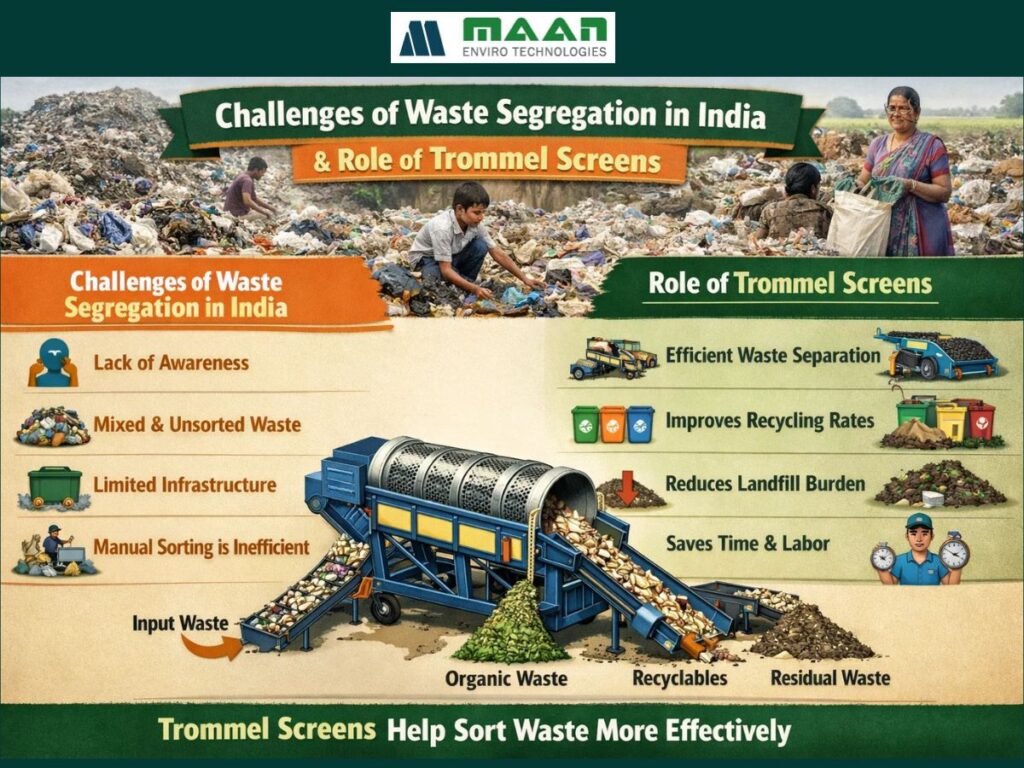

Waste segregation is the base of any solid waste management system. In India, where mixed waste is common and collection conditions vary widely, segregation remains one of the biggest operational challenges. Poor separation at source leads to low recycling rates, higher landfill load, and increased processing costs.

This is where mechanical screening equipment, especially the trommel screen (rotary screen), plays a practical role. By separating waste based on size, trommel screens help improve processing flow and support cleaner downstream operations.

Why Waste Segregation Is Difficult in India

India generates more than 160,000 tonnes of municipal solid waste per day, and a large part of it reaches processing plants in mixed form. Several factors make segregation difficult.

Mixed Waste at Collection Stage

Most waste collected from households and markets is not segregated into wet and dry streams. Organic waste, plastics, cloth, and inert material often arrive together at facilities.

Direct answer:

Mixed waste reduces recycling quality and slows down processing lines.

High Moisture Content

Organic waste in Indian cities often has high moisture levels due to food waste and climate conditions. This causes waste to clump together, making manual sorting difficult and unsafe.

Dependence on Manual Sorting

Many facilities still rely heavily on manual labour for segregation. This leads to:

- Inconsistent output quality

- Health and safety risks

- Lower recovery rates

Limited Space and Time

Urban waste plants often work under space constraints and tight processing timelines. Delayed segregation results in waste piling up, odour issues, and operational delays.

Why Mechanical Screening Is Needed

Manual segregation alone cannot handle large waste volumes efficiently. Mechanical screening helps create a structured flow before detailed sorting begins.

Role of Size-Based Separation

Waste segregation works better when waste is first separated by size. Smaller organic fractions can be treated differently from larger recyclables and rejects.

This is where rotary screening equipment becomes essential.

What Is a Trommel Screen (Rotary Screen)

A trommel screen (rotary screen) is a cylindrical drum with perforated openings. As the drum rotates, waste moves forward while smaller particles fall through the screen openings.

Basic Working Principle

- Mixed waste enters the rotating drum

- Rotation lifts and drops the waste

- Smaller fractions pass through the screen

- Larger items move to the end as oversize material

This simple process creates two or more waste streams for further handling.

How Trommel Screens Support Waste Segregation

Early Separation of Organic Waste

Fine organic material passes through smaller screen holes, helping separate wet waste early in the process. This improves composting and bio-processing outcomes.

Reduced Load on Manual Sorting

By removing fines first, trommel screens reduce the amount of waste that needs manual handling. Workers can focus on recyclable items rather than mixed waste.

Improved Flow in Processing Plants

Consistent screening helps maintain steady material flow across conveyors, separators, and balers.

Direct answer:

Trommel screens improve segregation by separating waste based on size before manual or automated sorting.

Waste Handling Efficiency Using Trommel Screens

Improving waste handling efficiency using trommel screens is one of the main reasons they are widely used in Indian waste projects.

How Efficiency Improves

- Faster movement of waste through the plant

- Lower downtime caused by blockages

- Better quality input for MRF systems

- Reduced wear on downstream equipment

For facilities processing 100–500 TPD of waste, even small improvements in screening efficiency can save hours of labour daily.

Common Applications in Indian Waste Projects

Municipal Solid Waste Processing

Trommel screens are used at the front end of MSW plants to separate organic fines from mixed waste.

Material Recovery Facilities (MRF)

Rotary screens prepare waste for manual and mechanical sorting by creating uniform material streams.

RDF Preparation

Screening removes fines and moisture-heavy material, improving the quality of refuse-derived fuel.

Composting and Bio-Waste Treatment

Organic-rich fines collected through trommel screens support better compost quality and reduced contamination.

Key Challenges Without Trommel Screens

Facilities that skip mechanical screening often face:

- Low recovery rates

- High reject percentage

- Increased manual labour costs

- Inconsistent output quality

In contrast, plants using rotary screens show better control over waste flow and segregation stages.

Factors That Affect Trommel Screen Performance

Screen Size and Hole Diameter

Smaller holes increase organic separation but reduce throughput. Larger holes allow higher capacity but may affect separation quality.

Waste Characteristics

Moisture level, plastic content, and particle size distribution influence screening efficiency.

Rotation Speed

Incorrect drum speed can cause material carryover or poor separation.

Direct answer:

Correct screen size and drum speed are key to effective trommel screen performance.

Why Trommel Screens Suit Indian Conditions

Indian waste streams are highly variable. Trommel screens handle this variation better than many fixed screening systems.

- Can process mixed and unsegregated waste

- Work well with high organic content

- Adaptable to different plant capacities

- Suitable for continuous operation

These features make rotary screens practical for both new and existing waste management plants.

Role of Maan Enviro Technologies in Waste Screening Solutions

Maan Enviro Technologies supports waste management projects by supplying solid waste processing equipment, including trommel screens, as part of integrated waste handling systems. The focus remains on practical design, smooth plant flow, and reliable operation under Indian waste conditions.

Frequently Asked Questions (FAQ)

What problem does a trommel screen solve in waste segregation?

A trommel screen solves the issue of mixed waste by separating material based on size. This allows organic waste, recyclables, and rejects to be handled separately, improving processing speed, safety, and recovery rates in waste management plants.

Is a Trommel Screen (Rotary Screen) suitable for mixed municipal waste?

Yes. Trommel screens are widely used for mixed municipal solid waste. They handle high moisture content and varied waste composition, making them suitable for Indian waste conditions where source segregation is often limited.

How does a trommel screen improve waste handling efficiency?

A trommel screen improves waste handling efficiency by reducing manual sorting, preventing conveyor blockages, and creating consistent waste streams. This leads to smoother plant operation, lower downtime, and better use of labour and equipment.

What size trommel screen is used in waste management plants?

The size depends on plant capacity and waste type. Small plants may use compact screens, while large municipal facilities use high-capacity rotary screens designed for continuous waste flow and heavy-duty operation.

Can trommel screens be used with other waste processing equipment?

Yes. Trommel screens are commonly used with conveyors, magnetic separators, air classifiers, and balers. This integration helps create a complete and organised waste processing line.

Final Takeaway

Waste segregation remains a major challenge in India due to mixed waste, moisture, and operational limits. The Trommel Screen (Rotary Screen) plays a key role by enabling early separation, improving waste handling efficiency, and supporting cleaner downstream processing. When used correctly, it helps waste facilities operate in a more stable and organised manner.

For a clearer view of how screening fits into daily plant operations, read Understanding Rotary Screen Working in Waste Handling Systems.