Table of Contents

Introduction: Why Waste Management Matters in Manufacturing Units

Manufacturing units across India generate large volumes of solid waste, including production residues, packaging materials, and organic waste from canteens and cafeterias. Improper disposal can lead to environmental hazards, legal fines, increased operational costs, and damage to corporate reputation.

Installing a solid waste management plant in India allows industrial units to manage waste efficiently on-site. It helps segregate, process, and convert waste into valuable products such as compost, Refuse Derived Fuel (RDF), and recyclable materials. These plants not only ensure compliance with Solid Waste Management Rules, 2016 but also contribute to cost savings, resource recovery, and a cleaner environment.

Understanding a Solid Waste Management Plant

Before installation, it is essential to understand the components and workflow of a solid waste management plant.

Segregation Units

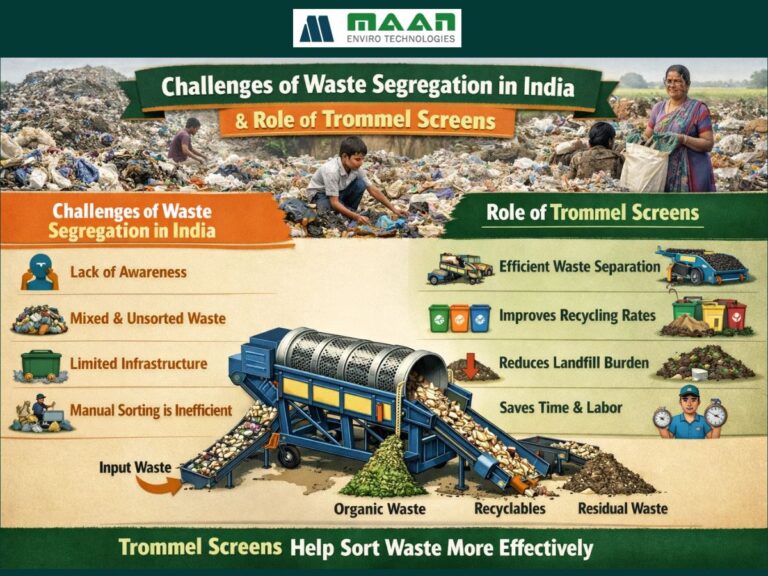

Segregation is the foundation of effective waste management. Components include:

Wet waste section for biodegradable material, such as food scraps, garden waste, and canteen leftovers

Dry waste section for plastics, metals, paper, and other recyclable materials

Hazardous waste handling for chemicals, oils, and industrial by-products

Processing Equipment

Industrial solid waste plants use various machines:

Trommel screens to separate materials based on size and type

Shredders and crushers to reduce volume and prepare waste for further processing

Composting machines for biodegradable material

RDF plant units for converting residual waste into fuel

Material Recovery Facilities (MRF) to sort and recover recyclables

Storage and Collection Systems

Modular bins, silos, and compactors ensure contamination-free storage

Proper flow from collection to processing units reduces operational delays

Output Handling

Compost can be used in landscaping or supplied to farms

RDF can be used as fuel in cement factories or power plants

Recycled materials can be reused internally or sold to recyclers

Step-by-Step Guide to Installing a Solid Waste Plant

Step 1: Conduct a Comprehensive Waste Audit

Identify the type, volume, and source of waste generated daily

Classify waste into biodegradable, recyclable, and hazardous categories

Note peak waste generation periods to determine plant capacity

Example: A food processing factory in Haryana produces 1.5 tonnes of organic waste and 0.5 tonnes of packaging material per day. A detailed audit helps in choosing the correct plant design and equipment.

Step 2: Plan the Plant Layout

Allocate areas for segregation, processing, storage, and finished product handling

Include access routes for vehicles and maintenance

Plan for future expansion with modular layouts

Ensure compliance with safety, ventilation, and fire regulations

Step 3: Select the Right Equipment

Choose fully automatic machines for high-volume waste processing

Semi-automatic units or modular machines are suitable for medium and small factories

Equipment should match waste type, daily volume, and desired output

Example: Maan Enviro Technologies provides customised solid waste plant solutions in India, including RDF plants, composting machines, and MRF units for industrial clients. Their solutions ensure compliance and operational efficiency.

Step 4: Obtain Permissions and Clearances

Apply for municipal and environmental approvals

Ensure compliance with SWM Rules, 2016, and local environmental guidelines

Maintain records of approvals for audits and inspections

Step 5: Installation and Testing

Professional installation ensures correct setup and machine calibration

Test each unit for throughput, efficiency, and safety

Train staff on operations, safety, and maintenance procedures

Step 6: Regular Operation and Maintenance

Implement standard operating procedures for segregation, feeding machines, and output handling

Monitor moisture, temperature, and compost or RDF quality regularly

Schedule preventive maintenance to reduce downtime and extend machine life

Benefits of Installing a Solid Waste Management Plant

Regulatory compliance with SWM Rules and local waste laws

Cost savings from reduced transport, disposal, and landfill fees

Resource recovery through compost, RDF, or recyclable materials

Operational efficiency with streamlined waste management and safer workplaces

Sustainability initiatives that enhance corporate image and attract environmentally-conscious clients

Fact: According to the Central Pollution Control Board, decentralised industrial waste management can reduce municipal landfill pressure by up to 60 percent in industrial zones.

Overcoming Common Challenges

Limited Space

Solution: Use vertical silos, compact machines, and modular layouts to maximise available space

Contaminated Waste

Solution: Implement strict source segregation, use trommel screens, and conduct regular staff training

High Initial Investment

Solution: Calculate long-term savings from reduced transport and disposal, and potential revenue from compost or RDF

Staff Training and Awareness

Solution: Provide hands-on training, standard operating procedures, and periodic performance monitoring to ensure efficiency

Real-World Industrial Examples

Automobile Manufacturer in Pune: Installed an RDF plant, reducing landfill disposal by 70 percent

Textile Factory in Gujarat: Uses shredders and composting machines to recycle fabric scraps and organic waste

Food Processing Unit in Haryana: Converts kitchen and garden waste into compost, which is supplied to local farms

These examples show how industries can adopt practical waste management solutions tailored to their needs.

Advanced Tips for Maximising Plant Efficiency

Monitor daily waste volumes and optimise machine operation schedules

Automate processes where possible to reduce human error

Conduct regular quality checks of compost, RDF, and recycled materials

Continuously improve segregation and processing methods based on data and results

Integrating Technology

IoT-enabled sensors can monitor machine performance and waste levels

Data analytics helps in predicting peak waste volumes and adjusting operations

Automated reporting simplifies compliance with municipal and environmental authorities

Common Questions About Solid Waste Plants

Which industries should install a solid waste plant?

Industrial units producing over 100 kilograms of waste per day, including production residues, food, and packaging materials, should install a solid waste plant for regulatory compliance and operational efficiency.

How long does installation take?

Installation timelines vary depending on plant size and equipment complexity. Typically, it takes four to twelve weeks, including municipal approvals, equipment delivery, and testing.

Can small-scale factories benefit from a solid waste plant?

Yes, modular or semi-automatic units are suitable for small and medium-sized factories, providing efficient segregation and processing of waste.

How much does a solid waste management plant in India cost?

Costs vary by capacity and automation. Small units typically start at ₹10 to 15 lakh, while large industrial plants can exceed ₹1 crore.

How can businesses maintain compliance with SWM Rules?

Proper segregation, correct operation of equipment, staff training, and maintaining detailed records of processed waste ensure continuous compliance.

Maan Enviro Technologies offers customised industrial waste management solutions, including plant installation, training, and maintenance support, ensuring efficient operations and regulatory compliance.

Conclusion

Installing a solid waste management plant in India is a practical, legal, and sustainable step for manufacturing units. From conducting a detailed waste audit and planning the layout to selecting the right equipment and performing regular maintenance, industries can manage waste efficiently and cost-effectively. Proper installation and operation lead to reduced landfill burden, resource recovery, and improved corporate reputation.

By adopting these steps, industrial units can create cleaner, safer, and environmentally responsible workplaces while remaining compliant with government regulations.