Industrial storage and display environments need materials that can carry weight, keep shape, and stay reliable through long use. This is why many storage system manufacturers choose industrial rigid PVC profiles in India for shelving, cabinets, warehouse racks, and display units. These profiles support strength at a lower weight, making them useful for factories, retail spaces, and equipment housings where stable structure is important.

Rigid extrusion profiles are used across many sectors because they offer clean dimensions, good bending resistance, and repeat production quality. They help reduce welding work, cut material waste, and support faster assembly. When used in storage systems, they let businesses install modular structures with less effort.

Why Rigid Profiles Are Used in Storage Systems

Rigid polymer profiles, especially those made from PVC, ABS, or polycarbonate, are shaped by extrusion. The process gives a uniform cross-section that stays consistent across long lengths. For industrial storage, this consistency matters.

Direct Answer

Rigid profiles work well in storage systems because they keep shape under load, resist impact damage, and support adjustable, modular designs that reduce assembly time.

Key Benefits:

Stable dimensions: help in tight fitting and smooth alignment

Impact resistance: protects the structure from daily handling

Light weight: reduces overall load without lowering strength

Low maintenance: saves time in cleaning and upkeep

Good finish: supports clean display and visual appeal

A study by a manufacturing group showed that rigid extruded parts can reduce assembly time by 28 percent compared to welded sheet structures, mainly due to uniform profiles and standard clips.

Types of Rigid Profiles Used in Industry

Not all storage systems use the same material. The choice depends on load, environment, and cost goals.

Common Materials

PVC: good strength, indoor durability, low weight

ABS: better impact resistance and heat performance

Polycarbonate: strong clarity and heavy-duty use

HDPE: good chemical resistance for factories

Each material is shaped through extrusion dies, allowing custom shapes for racks, trays, covers, and frame edges.

How Rigid Profiles Support Industrial Display Units

Industrial display systems need clean lines and a durable structure to hold products. Rigid profiles fit this need because they stay straight, even when long.

What Makes Them Useful

Uniform thickness prevents bending

Closed shapes add stiffness

Edge protection reduces sharp corners

Fast slot joints help modular setups

For example, a retail fixture company reported that using rigid PVC profiles helped them lower frame weight by 35 percent while keeping the same load rating for shelf units.

Rigid Profiles and Safety in Storage

Material safety matters in factories and commercial spaces. Rigid polymer profiles do not rust, do not conduct electricity, and are simple to clean.

Short Answer:

Rigid profiles improve safety because they remove sharp metal edges, avoid rust flakes near goods, and reduce electrical conduction risks.

With clean corner finishing, these parts also help protect packaging and internal products during movement.

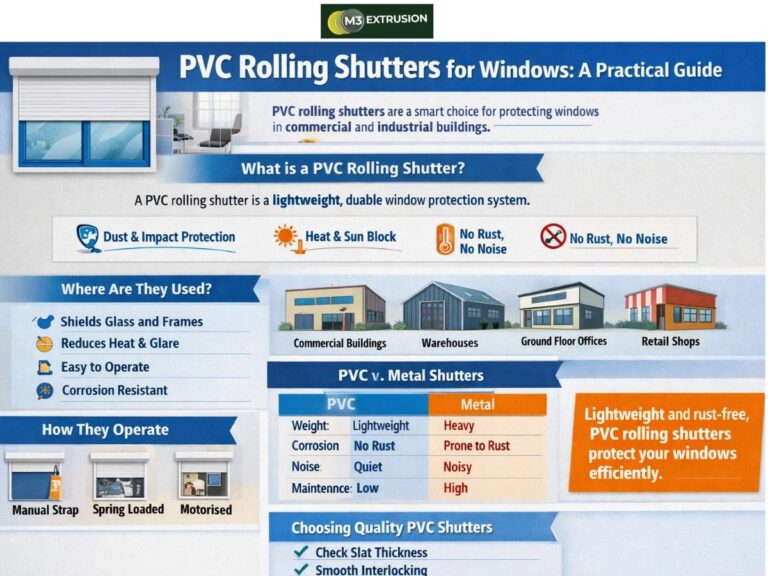

How Rigid Profiles Connect to Other Industrial Applications

Rigid profiles are not limited to storage and display units. The same extrusion technology is used in many building and construction needs. For example, rigid PVC for better buildings refers to the use of durable PVC shapes in interior frames, wall edges, window channels, and protective trims. This makes it simple for industrial buyers to align storage systems with building materials when planning a full facility setup.

This internal connection helps create a modular approach where storage racks, workstations, and wall fixtures follow a similar material base. Many manufacturers prefer this method because it reduces mixing of metals, speeds up installation, and keeps long-term maintenance low. When the same rigid extrusion parts are used in both storage and building systems, it becomes easier to manage spare parts and maintain consistent material strength.

How to Select the Right Profile

The best profile depends on load and operating temperature. Buyers can look at a few points before selecting extrusion parts for their project.

Checklist

Expected weight per shelf

Room temperature range

Indoor or outdoor use

Need for transparency

Chemical exposure

Batch size and supply plan

When buying in bulk, consistent supply is very important. A single extrusion supplier ensures matching dimensions in every batch.

Actionable Tips for Buyers

To get the best value, industrial users can follow a few steps:

Ask for test reports on load and bending.

Check tolerance values for lengths and angles.

Review edge finish quality for safety.

Confirm MOQ for bulk orders to keep price stable.

Look at tooling options when custom shapes are needed.

Companies like M3 Extrusion supply rigid profiles manufactured on order, which helps match dimensions to racks, cabinets, or display fixtures.

Examples of Use in Industry

Rigid profiles are found in many places:

Warehouse racks: frame edges and rail guides

Cold storage units: shelving and panel protection

Retail display fixtures: transparent fronts and channels

Electronics storage: anti-corrosion edges

Automotive units: small parts storage boxes

In a large warehouse project, using extruded components allowed the builder to assemble over 400 rack units in 7 days, saving labour time.

Durability and Cost Saving

Rigid profiles help reduce overall project cost because they are simple to cut, do not need painting, and can be reused when layouts change. This is useful for companies that update storage design often.

Short Answer:

Rigid extrusion parts last long indoors, lower maintenance cost, and support modular design updates.

Even after years, the shape stays stable if used in a controlled environment.

FAQ: Industrial Rigid Profiles

1. What are rigid industrial profiles?

Rigid industrial profiles are extruded shapes made from polymers such as PVC, ABS, or polycarbonate. They are used in storage racks, display units, and industrial enclosures. The solid structure keeps shape under load, reduces rust, and allows modular design with simple fittings.

2. Why are rigid profiles used in storage systems?

Rigid profiles are used because they offer strength at low weight, uniform shape, and clean edges. They reduce bending, support quick assembly, and stay safe for use around packaged goods. Their shape also helps achieve repeatable dimensions in large-scale storage projects.

3. Can rigid polymer profiles replace metal?

Yes, in many indoor systems. Polymer profiles are strong enough for shelves and display fixtures that do not need very high load capacity. They are easier to handle and cut, making them useful for modular storage projects in warehouses and retail environments.

4. Are extruded profiles safe for food storage units?

Some polymer profiles are safe for food-related environments if they meet relevant standards. They do not rust and are easy to clean. However, users should check the grade, surface finish, and any compliance requirements before use in food storage areas.

5. How long do rigid profiles last?

Rigid extrusion parts used indoors can last many years. Their lifespan depends on temperature, load, and cleaning methods. In normal use, they remain stable and hold shape without special maintenance. They also avoid corrosion, which supports long life.