On a cold morning, you can often feel the chill near a window even when the glass looks perfectly sealed. That cold edge is not just discomfort. It is usually a sign that the spacer inside the glazing is not doing its job well.

This is where advanced warm edge spacer profiles make a real difference. They change how windows perform, not just in theory but in everyday use. In modern buildings, warm edge technology has become an important part of efficient glazing, especially in commercial and façade projects.

This article explains how warm edge spacers work, why they matter in double and triple glazing, and what practical benefits they bring to real glazing systems.

Understanding Warm Edge Spacers in Glazing

A spacer is the component placed between glass panes in insulated glass units. It maintains the gap between panes and supports sealing systems.

A traditional spacer is usually made from aluminium or steel. These materials conduct heat easily, which creates thermal bridges at the edges of glass.

A warm edge spacer uses materials with lower thermal conductivity. This helps reduce heat transfer through the edges of the glazing unit.

In simple terms, a warm edge spacer in double glazing reduces heat loss where it usually happens most.

Why Spacers Matter in Double and Triple Glazing

In both double and triple glazing, most heat loss occurs at the glass edges, not the centre.

A well-designed insulated glass spacer improves:

- Thermal insulation

- Condensation resistance

- Structural stability

- Long-term durability

In triple glazing, the role of the spacer becomes even more critical because the system has multiple cavities and sealing points. A reliable triple glazing spacer helps maintain performance across all layers of glass.

Key Benefits of Warm Edge Spacers

1) Better Thermal Performance

Warm edge spacers reduce heat transfer at the edges of glass units. This leads to improved overall insulation.

In practical terms, this means:

- Less heat loss in winter

- Lower heat gain in summer

- More stable indoor temperatures

For building designers, this improvement can significantly affect energy ratings and compliance requirements.

2) Reduced Condensation at Glass Edges

Condensation often appears first at the edges of windows. This happens because traditional metal spacers create cold spots.

Warm edge spacers help maintain a more even temperature across the glass surface.

This reduces:

- Moisture buildup

- Fogging near edges

- Risk of mould formation

In commercial buildings, this is important for both performance and visual quality.

3) Improved Comfort in Interior Spaces

People sitting near windows often feel cold drafts or temperature differences.

By using warm edge technology, the temperature near window edges becomes more balanced. This improves comfort in offices, residential buildings, and commercial spaces.

A well-integrated glazing system does not just look good. It feels comfortable to use.

4) Longer Lifespan of Glazing Units

The durability of glazing depends on how well the spacer and seals perform over time.

Warm edge spacers:

- Reduce stress on seals

- Support stable bonding

- Improve resistance to thermal expansion

This leads to a longer service life for insulated glass units.

5) Better Performance in Façade Applications

Façade systems are exposed to extreme weather conditions, including heat, cold, wind, and moisture.

In such systems, warm edge spacers play a critical role in maintaining thermal efficiency and structural stability.

Many façade designers now prefer warm-edge spacer solutions for façades because they offer balanced performance across large glass panels and complex window systems.

Role of Warm Edge Spacers in Modern Glazing Systems

Warm edge spacers are not isolated components. They work as part of a complete glazing structure.

They interact with:

- Glass panes

- Sealants and adhesives

- Gas filling between panes

- Frame materials

- Overall glazing system components

When all these elements work together, the glazing unit performs more efficiently and reliably.

Real-World Example: Commercial Building Windows

In commercial buildings, large windows are common. These windows often use double or triple glazing for thermal performance.

With traditional metal spacers, building owners often notice:

- Cold zones near window edges

- Higher energy consumption

- Faster wear of sealing systems

After switching to warm edge spacers, many projects show:

- Improved insulation performance

- More consistent indoor temperatures

- Reduced condensation issues

This is why warm-edge technology is increasingly used in commercial glazing projects.

Practical Factors to Consider When Choosing Warm Edge Spacers

1) Material Composition

Warm edge spacers can be made from composite materials, plastics, or hybrid structures.

Each material affects:

- Thermal performance

- Flexibility

- Compatibility with sealing systems

2) Compatibility with Glazing Design

Not all spacers suit all glazing systems.

Check compatibility with:

- Double or triple-glazing design

- Glass thickness

- Sealant systems

- Frame types

3) Manufacturing Precision

Spacer performance depends on consistent dimensions and structural stability.

Manufacturers that specialise in custom profiles can produce spacers that match technical drawings and project requirements.

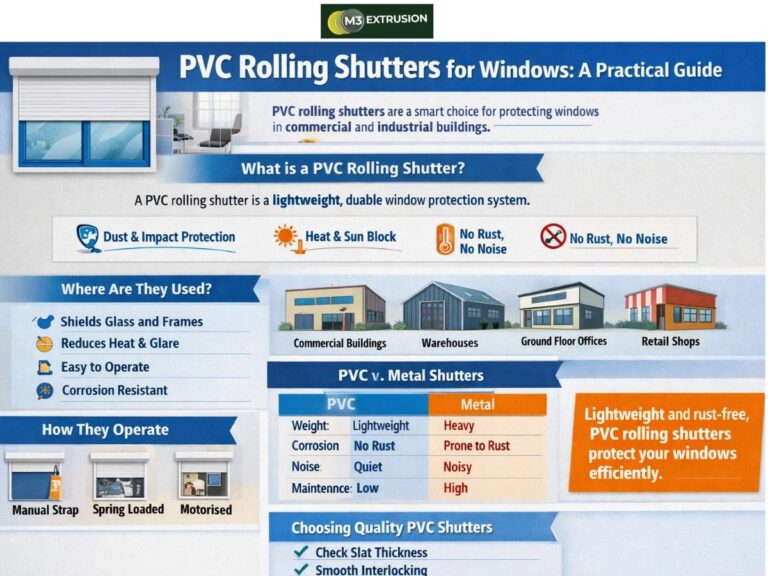

M3 Extrusion manufactures plastic profiles used in glazing applications, including spacer-related components, based on technical specifications and repeat production needs.

How Warm Edge Spacers Support Energy-Efficient Buildings

Modern buildings are designed with strict energy performance targets.

Warm edge spacers contribute to these targets by:

- Reducing thermal bridging

- Supporting high-performance glazing units

- Improving overall U values of windows

For architects and façade engineers, spacers are no longer minor components. They are key elements in energy efficient design.

Key Takeaways

Warm edge spacers play a critical role in improving the performance of double and triple glazing systems. They reduce heat loss, minimise condensation, and support long term durability of insulated glass units.

By integrating warm edge technology into glazing design, buildings can achieve better thermal performance, improved comfort, and more reliable window systems. In modern façades and commercial projects, warm edge spacers are becoming an essential part of high performance glazing.

FAQs

1) What is a warm edge spacer in glazing?

A warm edge spacer is a component placed between glass panes in insulated glazing units. It is made from low thermal conductivity materials to reduce heat transfer at glass edges. This helps improve insulation, reduce condensation, and enhance the overall performance of double and triple glazed windows.

2) How does a warm edge spacer improve double glazing performance?

A warm edge spacer in double glazing reduces thermal bridging at the edges of the glass. This leads to better insulation, fewer cold spots, and lower condensation risk. It also supports longer seal life and more stable performance in different temperature conditions within residential and commercial buildings.

3) Why is a triple glazing spacer important?

A triple glazing spacer is important because triple glazed units have multiple cavities and sealing points. The spacer helps maintain consistent spacing, supports sealing systems, and improves thermal efficiency. Without a reliable spacer, the performance benefits of triple glazing can be significantly reduced over time.

4) Are warm edge spacers suitable for façade systems?

Warm edge spacers are suitable for façade systems because they help manage thermal stress and improve insulation across large glass panels. They support stable performance in extreme weather conditions and contribute to energy efficient façade design in commercial and high rise building projects.

5) How do insulated glass spacers affect window durability?

An insulated glass spacer affects window durability by supporting seal stability and reducing thermal stress at glass edges. A well designed spacer helps prevent seal failure, moisture ingress, and structural deformation. This increases the lifespan of glazing units and reduces maintenance requirements over time.

6) Can warm edge spacers be customised for specific projects?

Warm edge spacers can be customised according to technical drawings, glass thickness, and system requirements. Custom designs allow better compatibility with glazing systems and façade structures. This makes them suitable for specialised commercial projects and repeat production where consistent performance is required.

Author Bio:

M3 Extrusion is a leading custom plastic extrusion manufacturer in India with more than 13 years of experience in polymer profile development. The company specialises in PVC, PC, ABS, and other extruded plastic profiles for lighting, construction, refrigeration, and industrial applications. With a focus on quality, innovation, and custom solutions, M3 Extrusion helps businesses achieve durable and precise extrusion results.