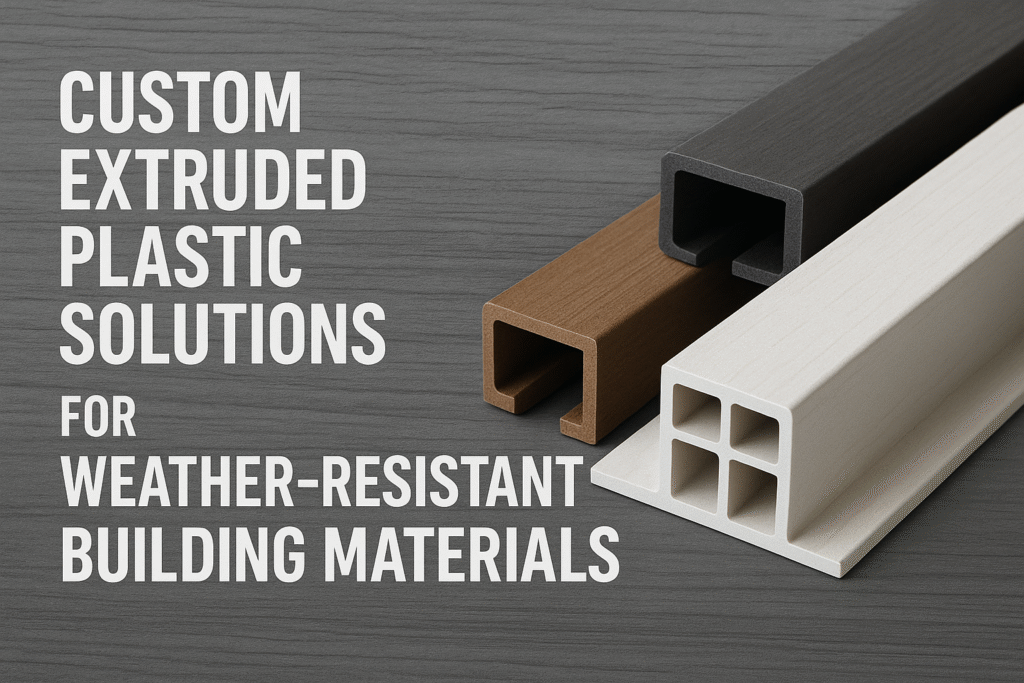

Building projects today demand materials that perform reliably in outdoor conditions. Sunlight, rain, and temperature fluctuations can compromise traditional materials such as wood or metal, leading to cracks, warping, or corrosion. Using custom extruded plastic in India provides a durable, weather-resistant alternative, helping manufacturers and builders reduce maintenance costs while delivering long-lasting structures.

Why Weather Resistance Is Critical in Construction

Weather resistance directly impacts the safety, aesthetics, and lifespan of a structure. Materials that degrade quickly under harsh conditions require frequent repairs and replacements, driving up project costs. Custom extruded plastics solve these problems by offering:

Moisture resistance – prevents swelling, warping, and rotting.

UV stability – retains colour and structural integrity even under prolonged sun exposure.

Thermal stability – maintains shape and performance despite temperature variations.

These qualities are particularly important for buildings in regions with heavy rainfall, high humidity, or extreme heat.

Advantages of Custom Extruded Plastic in Building Materials

1. Long-Term Durability

Extruded plastics do not absorb water or rust, making them ideal for applications exposed to rain or humidity. Window frames, wall panels, and cladding systems maintain their structural integrity for years, reducing the need for maintenance.

2. Design Flexibility

Custom extrusion allows manufacturers to create profiles in precise dimensions and complex shapes. Architects and engineers can achieve unique designs without the need for secondary processing, saving time and cost.

3. Strength-to-Weight Ratio

Plastic profiles are lightweight yet durable, making them easier to transport and install compared to metals. This reduces labour costs and the risk of installation damage, especially in large-scale construction projects.

4. Cost Efficiency for Bulk Orders

Bulk production of extruded plastics reduces per-unit costs and ensures a consistent supply. Companies can plan large projects confidently, knowing materials will meet specifications. (For detailed insights, see this guide on the 5 cost benefits of using custom extruded plastic in bulk orders).

5. Eco-Friendly Options

Some extruded plastics are recyclable and require less energy to produce than metals, reducing environmental impact. Using sustainable materials can also contribute to green building certifications.

Applications in Weather-Resistant Projects

Custom extruded plastics are widely used in construction and industrial projects, including:

Window and door frames – resistant to swelling, cracking, and fading.

Wall and ceiling panels – durable panels that handle moisture and temperature changes.

Cable conduits and electrical ducts – safe, reliable, and weather-proof protection for wiring.

Roofing trims and drainage components – lightweight, strong, and corrosion-resistant.

Facade systems – maintain structural integrity and aesthetic appeal under harsh weather.

These applications demonstrate how extruded plastics enhance project longevity and reduce maintenance burdens.

Case Examples and Practical Benefits

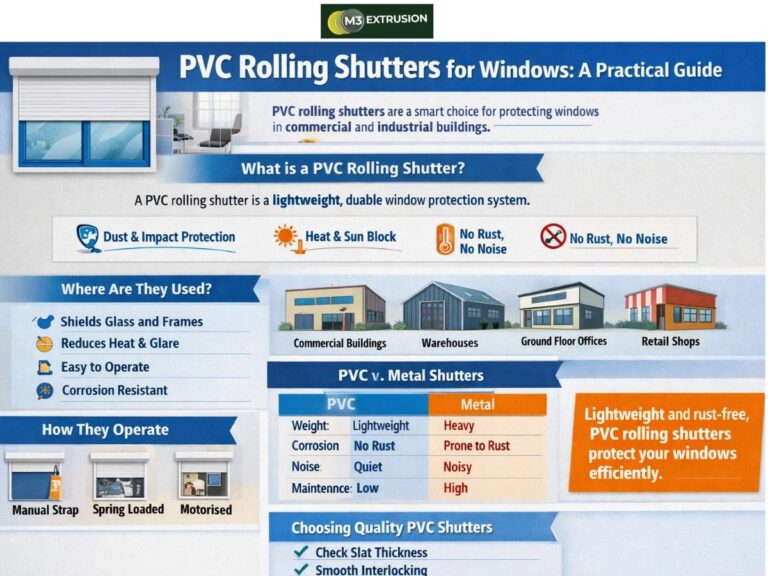

Residential Windows – Homes built in tropical regions often face heavy rains and high humidity. Using custom PVC extrusion for window frames prevents warping and leakage, extending the life of the installation by 15–20 years compared to traditional timber frames.

Industrial Wall Panels – Factories in coastal areas deal with salt-laden air, which corrodes metal panels quickly. Weather-resistant extruded plastic panels maintain structural strength while requiring minimal maintenance, reducing downtime and replacement costs.

Commercial Facades – Office buildings and shopping centres in sunny regions face UV degradation. Custom extruded plastic profiles maintain colour and finish over years, reducing repainting or replacement needs.

Bulk Orders: Why They Make Sense for Businesses

Ordering extruded plastic profiles in bulk provides multiple advantages:

Uniform Quality – Consistent material properties and dimensions across all profiles.

Lower Unit Cost – Economies of scale reduce manufacturing costs per piece.

Streamlined Logistics – Bulk shipments reduce packaging, transport, and handling costs.

Faster Project Completion – Reliable supply minimizes delays in large-scale construction or industrial projects.

Bulk orders are particularly beneficial for large-scale infrastructure, industrial facilities, and real estate developments where consistency and timely supply are critical.

Industry Trends and Market Insights

The global plastic extrusion market is expected to surpass USD 100 billion by 2030, driven primarily by construction and packaging sectors.

PVC and HIPS profiles dominate weather-resistant applications due to cost-effectiveness and durability.

In India, domestic extrusion companies are increasingly catering to both local and international demand, showing reliability in quality and bulk supply capabilities.

Studies indicate that extruded PVC windows can reduce energy costs by up to 15% in buildings due to their insulation properties.

These statistics confirm that weather-resistant extrusion solutions are becoming the preferred choice for durable, low-maintenance construction materials.

Solving Common Construction Challenges

Challenge 1: Frequent Maintenance of Traditional Materials

Solution: Using custom extruded plastic profiles eliminates water absorption, UV damage, and corrosion, reducing repair frequency.

Challenge 2: Delays Due to Material Inconsistency

Solution: Bulk orders of uniform extruded plastic ensure consistent quality across the project, preventing installation errors and rework.

Challenge 3: High Labour and Installation Costs

Solution: Lightweight profiles are easier to transport and install, cutting labour requirements and reducing risk of damage.

Challenge 4: Design Limitations

Solution: Custom extrusion allows precise dimensions and complex shapes, supporting unique architectural designs without extra machining or finishing.

Challenge 5: Environmental Concerns

Solution: Some extruded plastics are recyclable and require less energy to produce than metals, supporting sustainability goals and green building certifications.

Direct Answer: Why Choose Custom Extruded Plastic for Weather-Resistant Building Materials?

Custom extruded plastic is ideal because it combines durability, UV and moisture resistance, design flexibility, and cost efficiency. These attributes ensure long-term performance for construction and industrial applications while reducing maintenance and operational costs.

FAQs

Q1. What types of weather-resistant profiles can be made with extruded plastic?

Profiles for windows, doors, wall panels, roofing trims, facades, and electrical conduits are commonly produced using extrusion technology.

Q2. How does custom extruded plastic handle moisture and UV exposure?

It is non-porous, does not absorb water, and retains structural integrity and colour when exposed to sunlight or humidity.

Q3. Are extruded plastic profiles suitable for large-scale projects?

Yes. Bulk manufacturing ensures consistent quality, fast delivery, and cost savings for large construction or industrial projects.

Q4. Can extrusion be customised for unique architectural designs?

Absolutely. Shapes, sizes, and colours can be tailored to meet specific design and functional requirements.

Q5. How do bulk orders benefit businesses in the long term?

Bulk orders reduce per-unit costs, maintain quality consistency, ensure steady supply, and simplify logistics for large-scale operations.

Conclusion

Custom extruded plastic provides a durable, weather-resistant, and cost-effective alternative to traditional building materials. Its strength, flexibility, and low maintenance make it ideal for window frames, facades, roofing, and industrial applications. Bulk manufacturing further enhances efficiency, reduces costs, and ensures a reliable supply chain. Choosing extruded plastic profiles helps businesses deliver long-lasting, sustainable, and high-performance projects.