Industries today need materials that combine clarity, safety, and lasting strength. A polycarbonate transparent profile in India delivers all three, making it a reliable choice for construction, lighting, and manufacturing sectors. These profiles offer excellent visibility and durability, helping industries maintain safety and performance in demanding environments.

In India’s growing industrial landscape, polycarbonate profiles are steadily replacing glass and acrylic because they provide higher impact resistance, weather protection, and flexibility. They are commonly used in skylights, machine guards, lighting diffusers, and transparent wall panels.

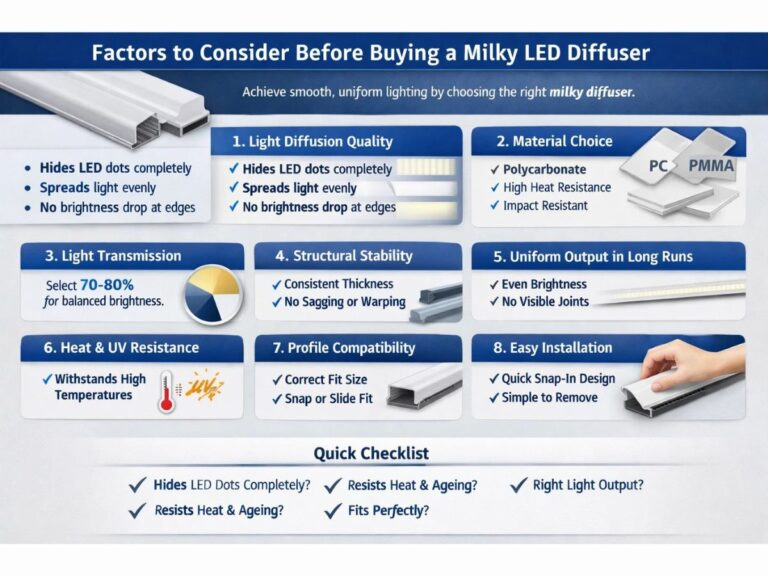

To understand how these profiles address common issues like light diffusion and structural strength, check out this helpful resource on solving diffusion and strength challenges.

Why Polycarbonate Transparent Profiles are Important

Every industrial setup requires materials that can handle stress, temperature shifts, and mechanical impact. Polycarbonate transparent profiles offer exceptional strength and optical clarity, making them dependable for both safety and design purposes.

Key advantages include:

Impact resistance up to 250 times higher than glass.

Light transmission of nearly 90 percent for bright, efficient lighting.

High thermal stability suitable for indoor and outdoor use.

These qualities make polycarbonate profiles a smart choice for businesses that value both durability and long-term performance.

Solving Diffusion and Strength Challenges

Transparent materials often struggle to balance toughness with clarity. Polycarbonate transparent profiles solve this problem by maintaining excellent light transmission while staying resistant to breakage. Their even light diffusion makes them ideal for both functional and aesthetic applications.

For example, polycarbonate diffusers in LED lighting systems distribute light smoothly across large areas, improving visibility and energy efficiency. In industrial environments, transparent machine covers made from polycarbonate allow operators to monitor processes safely while protecting equipment and personnel from debris.

Applications Across Industries

Polycarbonate transparent profiles serve multiple industrial and commercial purposes.

1. Lighting and Illumination

Used in LED housings, tube light covers, and diffusers, they improve brightness and energy efficiency in commercial and factory lighting.

2. Construction and Architecture

Perfect for skylights, roofing, and wall panels that require natural light and weather resistance.

3. Machinery and Equipment

Used for machine guards, inspection windows, and clear safety covers to enhance workplace protection.

4. Automotive and Transport

Employed in cabin dividers, light housings, and protective screens for safe, durable performance.

5. Retail and Display Applications

Used for display cases, signage, and retail fixtures that demand visibility and impact resistance.

Each of these applications highlights how polycarbonate profiles contribute to both visual appeal and operational safety.

Features that Enhance Safety and Performance

Impact Resistance

Polycarbonate profiles outperform glass and acrylic in strength, reducing the risk of damage during industrial use.

Weather and UV Protection

Their UV-stabilised surface maintains clarity and prevents yellowing under constant sunlight.

Lightweight Structure

They are easy to install, reducing labour and structural load.

Fire Retardant Quality

Their flame-retardant composition adds another layer of safety for industrial operations.

Customisation Options

Available in a range of designs, sizes, and finishes to suit specific project needs or bulk manufacturing orders.

Benefits for B2B Buyers

For B2B clients, polycarbonate transparent profiles offer a dependable material solution for long-term projects.

Bulk production ensures uniform quality across large orders.

Custom specifications support industry-specific applications.

Faster delivery helps maintain project schedules.

Cost-effective use over time due to durability and low maintenance.

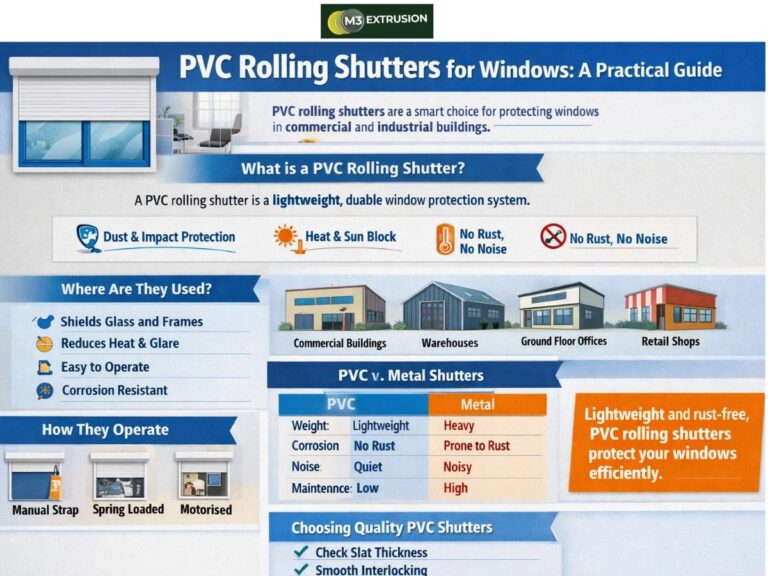

Companies like M3 Extrusion provide on-demand production and large-scale supply to meet the requirements of industries such as construction, lighting, and machinery manufacturing.

Technical Properties

| Property | Description |

|---|---|

| Density | 1.2 g/cm³ |

| Light Transmission | 85–90% |

| Impact Strength | 250x stronger than glass |

| Operating Temperature | -40°C to +120°C |

| UV Resistance | Excellent |

| Fire Rating | Self-extinguishing |

These properties demonstrate why polycarbonate profiles are ideal for high-performance and safety-critical environments.

Installation and Maintenance

For best results, industries should follow these steps:

Clean with mild, non-abrasive agents to maintain clarity.

Use appropriate sealants that do not chemically react with polycarbonate.

Allow space for expansion during installation.

Inspect fittings periodically for wear or loosening.

These maintenance practices ensure reliable performance and extend the product’s lifespan.

Why More Industries are Choosing Polycarbonate

With growing emphasis on safety and energy efficiency, more businesses are switching from glass and acrylic to polycarbonate materials. This change is driven by:

The need for impact-resistant, long-lasting transparent materials.

Energy savings from improved light diffusion and transmission.

A shift towards sustainable and recyclable materials in manufacturing.

By combining visibility, strength, and eco-friendliness, polycarbonate transparent profiles are shaping the future of industrial material use.

FAQ Section

1. What are polycarbonate transparent profiles used for?

They are used for lighting covers, skylights, machine guards, and industrial partitions, providing safety and visibility in demanding environments.

2. Why are polycarbonate profiles safer than glass?

They are up to 250 times stronger and do not shatter like glass, reducing the risk of accidents and downtime in industrial spaces.

3. Are polycarbonate profiles suitable for outdoor projects?

Yes. They resist UV radiation and weather conditions, retaining clarity and strength even after prolonged outdoor exposure.

4. Can I order in bulk or request custom sizes?

Yes. M3 Extrusion offers bulk supply and custom-manufactured polycarbonate transparent profiles to meet various industrial needs.

5. How long do polycarbonate profiles last?

They typically last 10 to 15 years or more with proper installation and regular maintenance.

Conclusion

Polycarbonate transparent profiles are one of the most reliable materials for combining safety, strength, and visibility. Their high impact resistance, clarity, and long service life make them a preferred choice for industries focused on performance and durability.

From construction projects to industrial lighting, these profiles provide dependable results that meet modern safety and design standards. They continue to prove that clear materials can be both tough and efficient, supporting long-term value for industrial and commercial users alike.