Condensation is a common challenge in industrial and commercial glazing. Factories, warehouses, and office buildings often face moisture build-up on windows, leading to reduced visibility, mould growth, and even long-term structural damage. A practical solution widely adopted today is the warm edge spacer in India, designed to improve insulation and prevent condensation around glass edges. By using advanced materials, these spacers provide both durability and energy efficiency, making them a smart choice for large-scale projects.

What Are Warm Edge Spacers?

A warm edge spacer is a narrow strip placed between two panes of glass in an insulated glazing unit (IGU). Its purpose is to hold the panes apart while reducing heat transfer and minimising cold bridges. Unlike traditional aluminium spacers, warm edge spacers use low-conductivity materials such as stainless steel, plastic composites, or hybrid blends.

This design keeps the glass edges warmer, significantly lowering the risk of condensation. For industrial settings, where large glass surfaces are common, this feature is critical in maintaining clarity and structural performance.

Why Condensation Is a Problem in Industrial Windows

Condensation might seem like a minor issue, but in industrial environments, its impact can be costly:

Equipment safety – Moisture can damage sensitive machinery.

Energy loss – Windows with condensation often indicate poor insulation.

Indoor air quality – Persistent dampness promotes mould and bacteria.

Maintenance costs – Continuous cleaning and repairs raise operational expenses.

By integrating warm edge spacers, industries can avoid these problems while creating a more efficient and healthier environment.

How Warm Edge Spacers Reduce Condensation

The reduction of condensation through warm edge spacers can be explained in three key ways:

Improved Edge Temperature

Traditional aluminium spacers conduct heat rapidly, creating cold spots on the window’s edges. Warm edge spacers keep the glass edges closer to room temperature, minimising dew formation.Better Thermal Break

Low-conductivity materials act as a thermal barrier, preventing outside cold from reaching inside surfaces. This limits condensation and enhances comfort indoors.Uniform Insulation

By reducing temperature differences between the glass centre and edges, warm edge spacers ensure stable insulation across the entire glazing unit.

Materials Driving Warm Edge Spacer Innovations

In recent years, manufacturers have experimented with various materials to boost performance. The leading ones include:

Stainless steel – Strong and corrosion-resistant while offering lower conductivity than aluminium.

Thermoplastic composites – Flexible, lightweight, and excellent in energy savings.

Hybrid systems – Combining metal and polymer for an effective balance of durability and insulation.

These materials are shaping the latest warm edge spacer innovations, helping industries achieve better thermal efficiency and longer-lasting glazing solutions.

Benefits of Warm Edge Spacers in Industrial Applications

Using warm edge spacers goes beyond condensation control. Industries gain multiple advantages, such as:

Energy efficiency – Reduced thermal bridging cuts heating and cooling costs.

Durability – Modern spacers resist UV exposure, pressure, and humidity.

Comfort – Workers enjoy clearer, drier windows and more stable indoor climates.

Sustainability – Better energy savings align with green building standards.

Key Statistics That Highlight Their Value

Studies show that warm edge spacers can improve window U-values by up to 10%, leading to notable energy savings in large buildings.

Research in commercial glazing indicates that condensation reduction extends glass life by 15–20%, lowering long-term replacement costs.

In industrial projects, energy-efficient glazing with warm edge spacers can cut annual HVAC expenses by 5–8%, especially in regions with extreme weather.

Choosing the Right Warm Edge Spacer for Industrial Windows

When selecting a warm edge spacer, consider these factors:

Project size and type – Large facilities may benefit more from hybrid materials for durability.

Climate conditions – Areas with high humidity demand spacers with strong moisture resistance.

Energy goals – For green-certified buildings, thermoplastic composites often align best with sustainability targets.

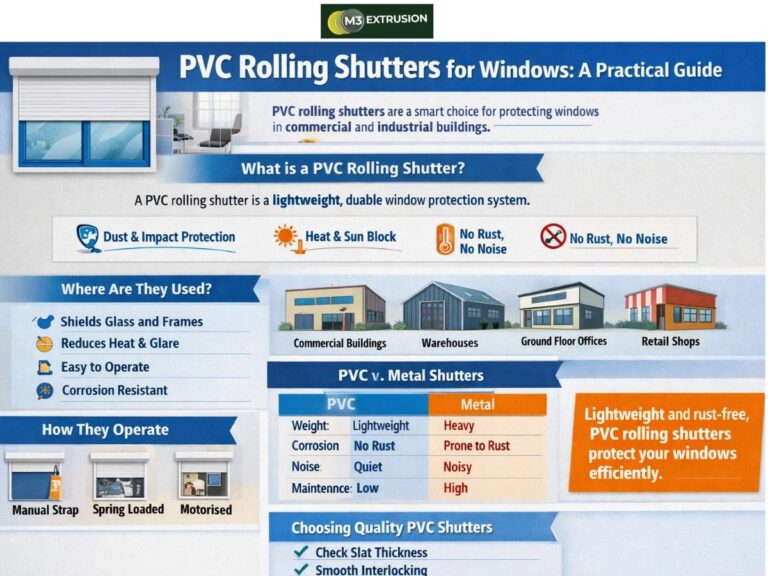

Supplier capabilities – Choose manufacturers with consistent bulk supply and order-based production, such as M3 Extrusion.

FAQs on Warm Edge Spacers

1. What is the main purpose of a warm edge spacer?

A warm edge spacer reduces heat transfer at the glass edge in insulated glazing units, keeping the edges warmer and preventing condensation.

2. How do warm edge spacers benefit industrial windows?

They minimise moisture build-up, lower energy costs, and extend glass durability, making them ideal for large commercial and industrial facilities.

3. Are warm edge spacers better than aluminium spacers?

Yes. Aluminium conducts heat quickly, creating cold spots, while warm edge spacers use low-conductivity materials that keep edges warmer and reduce condensation.

4. What materials are used in warm edge spacers?

Common materials include stainless steel, thermoplastic composites, and hybrid polymer-metal blends, each offering unique durability and insulation benefits.

5. Can warm edge spacers help with energy savings?

Yes. They reduce thermal bridging, which improves window insulation and can cut heating and cooling costs in industrial buildings by up to 8%.

Conclusion

Warm edge spacers are an essential part of modern industrial glazing, offering a practical way to reduce condensation, lower energy use, and improve indoor comfort. By selecting the right material and supplier, businesses can achieve long-term value while ensuring reliable performance in demanding environments.